HaiStation

(2022年12月15日)https://www.hairobotics.com/products/haistation

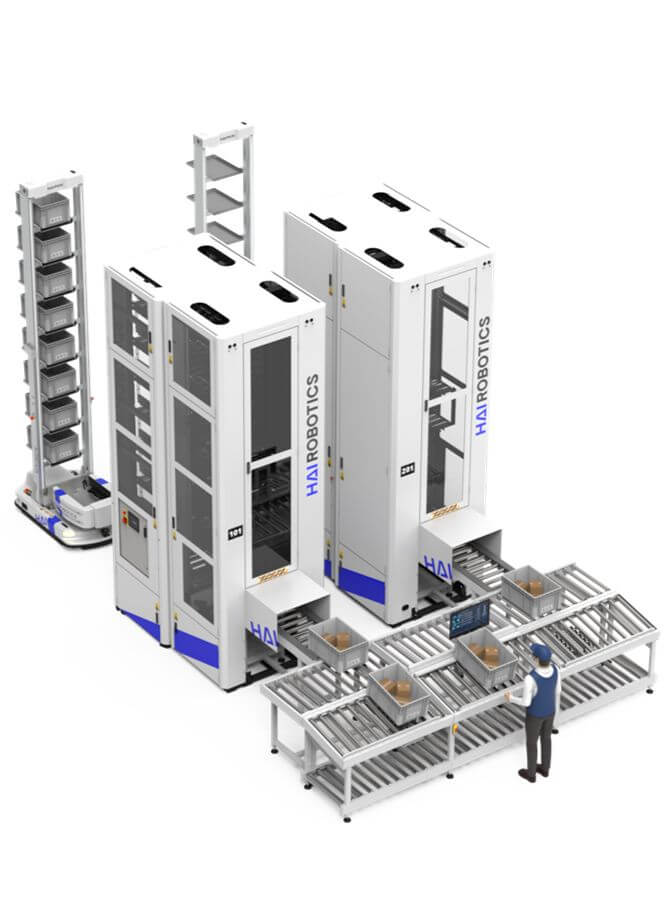

In the complete Goods to Person solution, HaiPick robots are dedicated to improving transport efficiency from warehouse to workstation. Hai Robotcs also developed HaiStation, which is used to improve the efficiency of workstations to order cases.

HaiStation is a product portfolio that is composed of including HaiPort workstation, conveyor, put wall, buffer wall, workstation, robotic arm etc. As the backend of the whole warehouse solution, HaiStation provides ultra-efficient case loading and unloading connect to frontend robots with safety human-robot interactions.

Enables more efficient loading and unloading of cases. Significantly increases HaiPick ACR's efficiency.

Fully automated inbound and outbound logistics. Workers and robots are separated to run processes in a secure way.

Ergonomic design provides a seamless human-to-system interaction, providing maximum in-and-outbound efficiency.

HaiPort-powered Workstation

HaiPort-powered workstation is an automatic loading and unloading machine. It is composed of HaiPort, conveyor, visual Kanban, put wall, pick to light system, and can easily dock with HaiPick ACR to automatically unload, transport, and load cases from the robot's storage tray, optimizing inbound and outbound processes.

The workstation enables more efficient loading and unloading of cases. It can load 8 cases in 3 seconds and unload 8 cases in 5 seconds, which significantly increases HaiPick ACR's efficiency.

Its modular design, flexibility, and easy transport capabilities support rapid increase/decrease of equipment, meeting high efficiency and low cost requirements. Workers and robots are separated to ensure safety. The ergonomic design of the on-robot picking workstation delivers convenient operation, high efficiency, and low cost.

On-conveyor Picking Workstation

The on-conveyor robotic workstations automatically conveys the cases unloaded by the HaiPick robot or the cases that need to be loaded, realizing automated storage and retrieval functions. It is composed of a conveyor line, visual Kanban, shelves, and pick to light system.

It offers an ergonomic design, the workers and HaiPick robots are indirectly connected, and the goods can be sorted on the conveyor line without too much movement. It delivers convenient operation and efficient warehousing.

Intelligent Sorting

The visual system Kanban manages work, guiding workers to sort goods more efficiently.

For more information about robotic picking system warehouse solutions, please feel free to contact us!

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント