Titanium Dioxide Wastewater

(2020年01月23日)https://www.jiuwumembrane.com/application/titanium-dioxide-wastewater.html

A large amount of waste acid is produced in the production of titanium dioxide, a large amount of high-salt wastewater is generated in the post-treatment process, and some titanium dioxide is still lost after the CN filter. On the one hand, the titanium white industry suffers from increasingly strict Environmental constraints, on the other hand, waste acid, water, and titanium dioxide resources are huge. Therefore, titanium dioxide water treatment has received an increasing attention. JIUWU has developed a series of membrane treatment technologies for waste acid treatment, titanium dioxide recovery, and water reuse.

Technical introduction

The membrane process is based on membrane separation technology. The salt and acid in the waste acid, the salt, and water in the waste brine are separated to achieve the acid and salt in the waste acid, and the salt and water in the brine can be reused. The removal rate of the metal salt in waste acid is over 98%, the recovery of titanium dioxide is 99.99%, and the water production index reaches the international first-class standard. The separation membrane is a cross-flow filtration method, which greatly reduces membrane fouling, delays the rate of membrane fouling, and improves ceramic membrane technology efficiency.

Process

Titanium dioxide production includes two production methods, sulfuric acid, and chlorination. For two different production methods, JIUWU has designed different membrane processes.

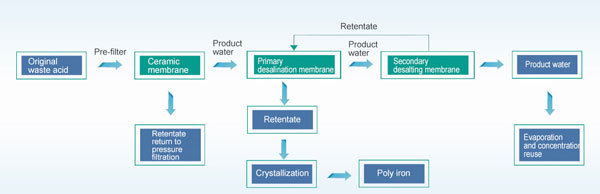

1. Titanium white waste acid treatment process for sulfuric acid method

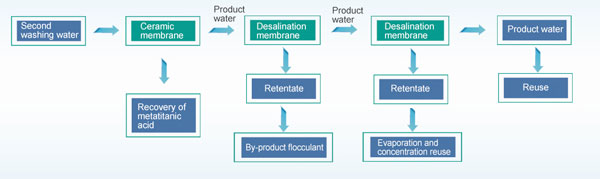

2. Titanium dioxide second washing water treatment process for sulfuric acid method

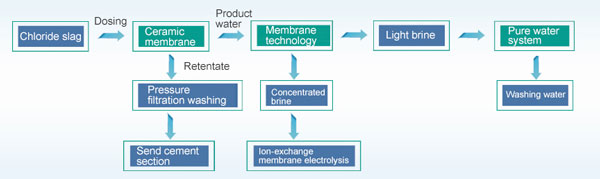

3. Titanium white chloride slag water 'zero liquid discharge' for chlorination method

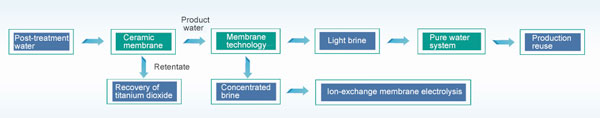

4. Titanium white post-treatment water reuse process for chlorination method

Process advantages

Product water quality: The SS is less than 1ppm, the turbidity is less than 0.5NTU, and the effluent water quality is stable;

Save land occupation: Membrane process replaces sedimentation tank, land occupation is much smaller;

Long work life: Acid and alkali resistant, high temperature resistant and high-pressure resistant, work life is longer than 5 years;

Easy operation: Short process, less control point, DCS control

High effectiveness: Short separation process, continuous operation, short wash cycle

Circular economy: Full recovery of titanium dioxide, product water recycle, chlorination method Titanium white process combined with caustic soda process form the environmental protection industry chain.

JIUWU HI-TECH has many unique membrane applications and more than 50 Patents regarding ceramic membranes, Organic membrane filters, systems and process applications, in areas such as Food & Beverage, Bio-Pharm, Environmental and the Chemical Industry. We sincerely invite and welcome people from all around the world to invest and create more values together.

- このできごとのURL:

コメント