Power Generation

(2020年06月09日)http://www.seawaterchlorination.com/application/power-generation.html

Description

Thermal power plants powered by either nuclear energy or fossil fuel located along a seacoast normally use seawater as a coolant in the steam condensers. These are typically once through cooling water systems.

Chlorination system in power plant in above mentioned types of application has considered as the most effective, low operating cost and safety operation method in order to control the marine growth at the seawater intake structure.

Onsite hypochlorite package well known as the best method to prevent accumulations of marine life in the seawater intake line of the various plants, because no dangerous liquid or gaseous chlorine is required.

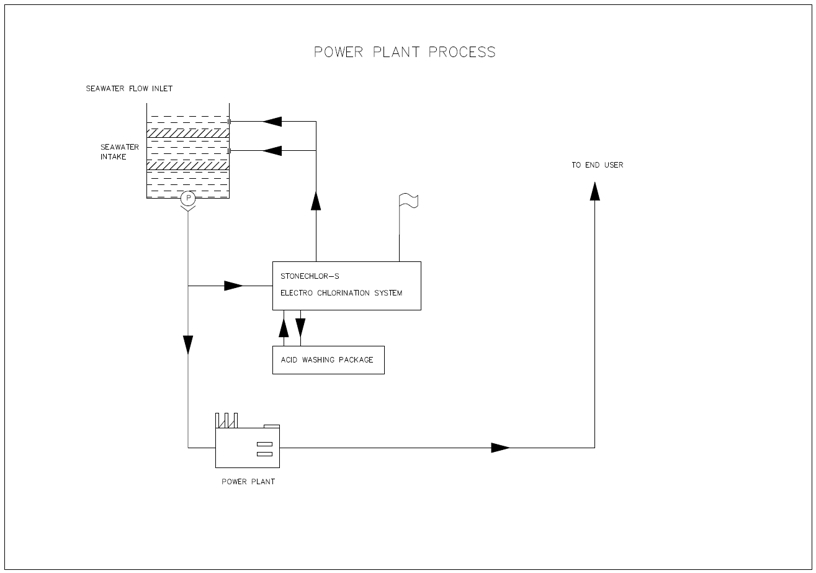

Process Flow

Bio fouling control is one of the main challenges in the upstream processes of the power station is to protect pipeline and process equipment against biological fouling.

Restriction of cooling water flows, acceleration of corrosion and a reduction in the overall life of process equipment can all be controlled by the effective design of our electro chlorination package.

Seawater electrochlorination system packages play an effective role in optimizing flow assurance.

Raw seawater is fed into the package inlet at the designed flow rate via a side stream from the main seawater process line.

Once controlled, the seawater is passed through the electrolytic cell which are fed an electrical supply from the package rectifier.

Depending on pressure available this seawater flow will be pressure controlled or boosted to provide the optimum operating pressure and flow rate (required for the chosen electrolytic cell configuration).

The rectifier is designed specifically for the requirements of the installed electrolytic cell. It converts the AC platform input voltage into the required low voltage DC current and regulates this output to a selected and controlled level.

Electrochlorination process takes place within the electrolytic cell as per the following equation:

At the anode: 2 Cl - 2 e → Cl2

At the cathode: 2 Na+ 2 H2O + 2 e→ 2 NaOH + H2

Overall: 2 NaCl + 2 H2O → 2 NaOCl + 2 H2

Through the electrolysis process the package produces the required amount of sodium hypochlorite together with the by-product, hydrogen gas.

The solution with hydrogen gas are fed into degassing tank (Or cyclone degassing separator) and the hydrogen to vent to open atmosphere.

The hydrogen free solution containing sodium hypochlorite is then dosed into the seawater circuit through dosing pumps or gravity.

- このできごとのURL:

コメント