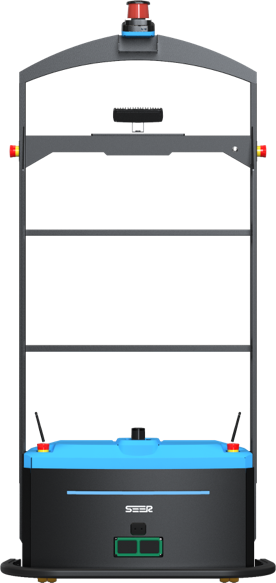

Automated Forklift SFL-MP10S

(2021年)https://www.seer-group.com/robot/SFL-MP10S

The Automated Forklift SFL-MP10S 2021 is based on the second generation of laser SLAM ground forklift automatic trucks. This automated forklift has a small shape and strong load capacity. The SRC series core controller is equipped inside to achieve ±10mm high precision positioning; And with infrared sensors, 3D obstacle avoidance, safety edge contact and other sensors for safety protection, this automated forklift can ensure the safety of people and goods in the process of operation. It can flexibly complete the transport of goods in a narrow space and realize the intelligent logistics of the factory "handling magic".

Descriptions

Descriptions of Automated Forklift SFL-MP10S

Customized laser height

The navigation lidar is installed on the top of the bracket. Also, the original location of the navigation lidar is replaced with an obstacle avoidance lidar.

Accurate obstacle avoidance

3D obstacle camera makes a route to achieve perfect obstacle avoidance.

More reliable anti-collision system

Increase the anti-collision bar at the bottom of the fuselage and support a variety of sensors for safety protection to ensure the safety of staff, goods and robots during operation.

Pallet recognition

Pallet recognition+Accurate handling

Automatic charging

Support automatic charging with no staff intervention.

Specifications

Products Comparison

Specifications of Automated Forklift SFL-MP10S

model

Product modelSFL-MP10S

The product nameLaser SLAM ground automatic forklift truck

Technical parameters

Dynamic formelectric

Driving wayAutomatic navigation

Navigation wayLaser SLAM

Tray typeSichuan words

Rated load capacity800kg

Center distance of load600mm

The wheelbase842mm

Dead weight (battery included)210kg

Navigation position accuracy 1±10mm

Navigation Angle accuracy 10.5°

Forks in place accuracy 1/

Standard hoisting height70mm

The height of the gantry/

Height of fork surface above ground (when the fork is the lowest)86/106mm

Navigation laser scanning altitude1800mm

Vehicle size: length * width * height1515*885*1835mm

Fork size: length * width * height1154*186*60mm

Goods fork out wide570/680mm

Right-angle stacking channel width, pallet 1000×1200 (1200 cross forks placed)1990mm

Right-angle stacking channel width, pallet 800×1200 (1200 is placed along the fork)1900mm

Map Area (Single)≤ 400000m²

Minimum turning radius1035mm

The performance parameters

Driving speed: full load/no load0.6/0.8m/s

Lifting speed: full load/no load/

Descent speed: full load/no load/

Portal moving speed: full load/no load/

Passability (slope/step/gap)2< 5/5/10%/mm/mm

Driving motor power (S2, 60 min)0.6kW

Lifting motor power (S3, 15%)0.8kW

Steering motor power (S2, 10 min)/

Service braking modeElectromagnetic brake

Drive control modeSpeed feedback

The wheels

Tyre type: drive wheel/support wheelPU/PU

Tire size: drive wheel100mm

Tire size: load-bearing wheel80mm

Tire size: Balance wheel/

Number of wheels: driving wheel (×= driving wheel)/ bearing wheel/

Wheel base: bearing side/

Wheel base: drive side400mm

The battery

The battery specification48/35V/Ah(The ternary lithium)

The battery weight15kg

Comprehensive range of8h

Charging time (10%-80%)2h

Charge formAutomatic/manual

Battery cycle number> 500

certification

ISO 3691-4×

EMC/ESD√

UN38.3√

RoHS√

REACH√

Functional configuration

Wi-Fi roaming function√

3D Obstacle Avoidance 3⚪

Remote emergency stop 4⚪

Pallet identification 3⚪

Cage stack 3⚪

High shelf pallet identification 3⚪

Stack plate damage detection 3⚪

Pallet stacking and unstacking 5⚪

The HMI screen√

Fork tooth distance sensor√

Cargo weight survey√

Security configuration

Scram button√

Acousto-optic instructions√

Braking distance: 1m/s / 1.5m/s≤30 / ≤50mm

Vehicle hardware fault detection√

360° laser protection√

Article crash√

High safety protection of fork teeth√

other

Network communication4G / 5G / Wi-Fi 802.11 a/b/g/n/ac

The flatness of the ground±5mm/m²

Scenario requiresOnly suitable for indoor, light intensity: ≤40 KLX (IEC 61496-3), no oil and water on the ground and other scenes

Ambient temperature and humidity rangeTemperature: 0-50℃ / Humidity: 10-90%, no compression condensation

The IP ratingIP20

Driver's ear noise according to EN12053≤70dB(A)

√The standard

×There is no

⚪optional

1. Navigation accuracy usually refers to the repeated accuracy of the robot's navigation to the target site, when the environment scanned by the robot lidar is relatively stable (rate of change <

30%), the robot can navigate from a fixed direction to the target site with the desired repeatability.

When the robot runs along the virtual path, it will try to fit the path, but repeatability is not guaranteed.

In other words, the robot can guarantee the accuracy of arrival, but not the accuracy of navigation path fitting.

Fork positioning accuracy refers to the error range of a forklift truck when it is rising or descending to a specified height.

2. The road surface is smooth and clean, without obvious ups and downs.

Slope 5% = arctan(0.05) ≈ 2.8°.

The robot cannot stop or turn at the ramp, step or gap, and can only pass quickly perpendicular to the ramp, step or gap.

3. Seer identification camera and algorithm authorization are required

4. It needs to be used with SEER system.

5. Comply with SEER stacking and de-stacking technical requirements.

Compared with many other autonomous mobile robots manufacturers, our company is the best choice for you.

Pictures/Videos

Pictures/Videos of Automated Forklift SFL-MP10S

- このできごとのURL:

コメント