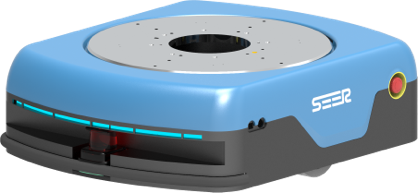

Automated Mobile Jacking Transfer Robots SJV-SW500

(2021年)https://www.seer-group.com/robot/SJV-SW500

Laser Slam Omni-directional Latent Automated Mobile Robots SJV-SW500, equipped with SRC series core controller, has an ultra-low chassis, so that it can drill into the shelf for jacking and transfer with a limit load of 600kg. This amr transport tracking robot has various navigation methods and flexible deployment. Its slim body enables to move in all directions easily. SEER Group, one of the professional autonomous mobile robots companies, manufactures autonomous and mobile robotics of high quality.

Descriptions

Descriptions of Automated Mobile Jacking Transfer Robots SJV-SW500

Rotating Tray

The pallet can be rotated 360° arbitrarily to control the states of the goods.

Stable Navigation

Built-in industrial-grade WiFi client equipment makes network data interaction more stable.

Shelf Identification

The location and posture of the pallet are accurately and autonomously identified through the pallet identification sensor. Efficient and precise forking of cargoes can be realized even

if the pallet is moved.

Autonomous Charging

Automatic charging is supported, requiring no staff intervention during the charging operation.

Specifications

Specifications of Automated Mobile Jacking Transfer Robots SJV-SW500

Products Comparison

Basic parameters

Product modelSJV-SW500

Navigation methodLaser SLAM

Drive modeTwo-wheel differential

Shell colorBlue and black/Customized color

L*W*H924*762*300mm

Rotation diameter1035mm

Weight (with battery)200kg

Load capacity500kg

Chassis ground clearance25mm

Lifting platform dimensionsØ600mm

MAX. lifting height60±2mm

Lifting time8±0.5s

Laser scanning height159mm

NetworkEthernet / Wi-Fi 802.11 a/b/g/n/ac

Temperature and humidity rangeTEMP: 0-50℃ / RH: 10-90%, no compression, no condensation

IP rating[1]IP20

Performance parameters

Passability (slope/step/gap)[2]< 5%/5mm/30mm

MIN. passable width880mm

Navigation position accuracy[3]±5mm

Navigation angle accuracy[3]±0.5°

Navigation speed≤ 1.6m/s

Map area (single frame)≤ 400000m²

Battery parameters

Battery specifications48/40 (Lithium Iron Phosphate)

Comprehensive battery life10h

Charging time (10-80%)≤1h

Charging methodManual/Automatic

Battery cycles> 2000

Configurations

Number of lidar1(SICK nanoScan3 / P+F R2000-HD)

Cargo detection×

E-stop button√

Speaker√

Atmosphere light√

Bumper strip√

Features

Basic features[4]√

Wi-Fi roaming√

Automatic charging[5]√

Shelf recognition√

Tray spin[6]√

Precise locating with PGV[7]〇

QR code navigation[8]〇

Laser reflector navigation〇

Certifications

EMC/ESD√

UN38.3√

RoHS√

REACH√

1.The road surface should be smooth, clean and free of obvious ups and downs. Slope 5% = arctan (0.05) ≈ 2.8°. The robot must not stop or turn at the ramps, steps, or gaps, but can pass quickly perpendicular to them.

2.The localization accuracy is affected by environment, ground, etc. Please refer to the localization accuracy interpretation in the final technical agreement.

3.Basic functions include but are not limited to map editing, model editing, localization module, navigation module and API interface.

4.Need to be used with a dedicated automatic charging pile.

5.Need to be used with Pepperl + Fuchs PGV100-F200A-R4-V19 QR code scanner.

6.SJV-SW500 is designed for indoor transportation only and is not recommended for outdoor use.

As an autonomous forklift company, we have a lat of products for customers to choose.

Pictures/Videos

Pictures/Videos of Automated Mobile Jacking Transfer Robots SJV-SW500

- このできごとのURL:

コメント