A Manufacturing Method of the Shell Mould for High Voltage Circuit Breaker Mould

(2022年)https://www.waiwaitree.com/bmc-smc-products/circuit-breaker-housing.html

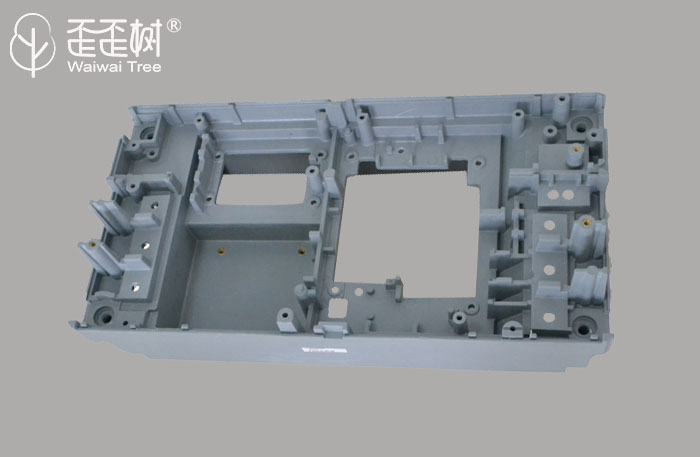

High Voltage Circuit Breaker Mould belongs to the field of high-voltage electrical equipment, which comprises a mold on the shape and a mold under the shape. The external upper die includes an upper supporting plate and an upper half model, and the upper supporting plate is a plate-like body. The upper half model has the same external shape as the left half of the parting surface composed of the horizontal and vertical cylinder centerlines of the shell. The external lower die comprises a lower supporting plate and a lower half model, and the lower supporting plate is a plate-like body. The plane composed of the lower half model and the transverse and vertical cylinder centerlines of the shell is the same as the outer shape of the right half of the parting surface. In the intersection part of the inner cavity and the shape, a convex block with the same section shape as the outlet of the inner cavity is set as the installation structure of the inner mold. It can be equipped with the inner cavity mold after the molding is completed, and its parting surface part is fixedly connected with the upper supporting plate. It has the characteristics of reasonable and even molding distribution, small deviation after the upper and lower mold is closed, and reducing the casting scrap rate caused by the molding deviation.

Aobang provide bmc composite, grp roofing materials, gfk material, shell moulding and etc. Contact us to buy bmc composite or know more.

- このできごとのURL:

コメント