SMC Materials in the Application of Auto Parts

(2022年)https://www.waiwaitree.com/auto-parts-and-accessories/

SMC is a new type of material. Auto parts made of this material have the advantages of light weight, high strength, corrosion resistance, and dimensional stability, and the advent of SMC materials has greatly promoted the development of the automotive industry. The development of industry has pushed SMC to a new level. Its advantages such as mass production and low cost have been valued by more and more automobile manufacturers.

The sheet is made on the SMC forming unit, and the upper and lower parts of the sheet are covered with film. After curing, a certain amount is weighed and placed in the SMC mold, and then molded on the press. The production cycle is generally about 5 minutes, and the fastest is only 30 seconds. Even complex products can be molded at one time. Therefore, SMC has the advantages of saving manpower, reducing processing procedures, and facilitating mass production. SMC materials have been widely used in automotive materials instead of steel.

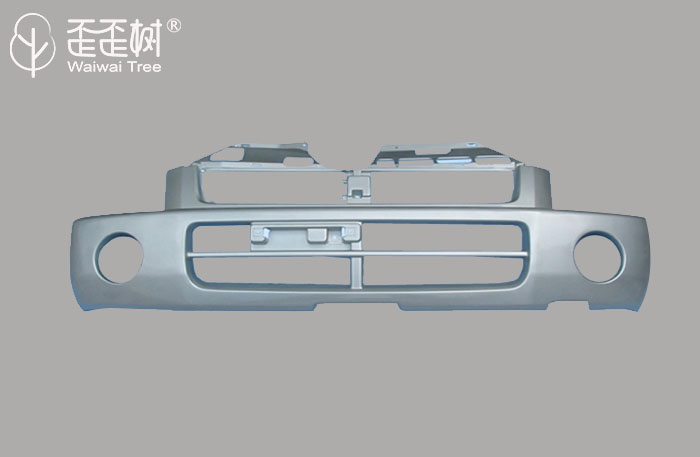

With SMC technology, various sizes and shapes of SMC auto parts can be manufactured. Designers can easily design parts of different thicknesses and shapes, such as bumpers, car seats, etc., according to product needs, which can show the designer's rich design scheme to the maximum extent, fully reflect the flexibility and freedom, and speed up the model update speed.

Zhejiang Aobang Technology Co., Ltd. relies on advanced manufacturing concepts, production technology, and proprietary application technology. The SMC materials produced by Zhejiang Aobang Technology Co., Ltd. enjoy a high reputation in the new energy vehicles and automotive industries. Welcome to consult and buy!

Aobang provide bmc composite, bmc molding, shell moulding and etc. Contact us to know more.

- このできごとのURL:

コメント