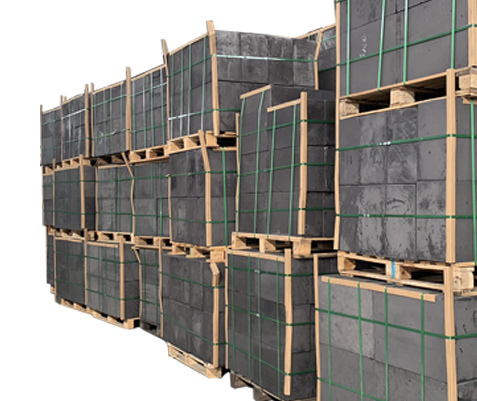

GRAPHITE BLOCKS FOR SALE

(2023年01月12日)https://www.whgraphitesupplier.com/products/graphite-block/

Graphite blocks for sale are generally divided into natural china graphite block and artificial graphite block. The most widely used ones are artificial graphite blocks. As one of the biggest graphite block supplier in China, WH Graphite can provide you with all kinds of OEM graphite block as you need.

Graphite is an allotroph of carbon, gray black, opaque solid, melting point of 3652℃, boiling point of 4827℃. Solid carbon large graphite block, a stable chemical property, is corrosion resistance, and is hard to react with acid, alkali and other agents. Carbon graphite block burns in oxygen at 687℃ to form carbon dioxide. It can be oxidized by strong oxidants such as concentrated nitric acid and potassium permanganate. The graphite carbon block also can be used as an antiwear agent or lubricant. High purity graphite as a neutron decelerating agent in the atomic reactor, can be used to manufacture graphite crucible, electrode, brush, dry cell, graphite fiber, heat exchanger, cooler, arc furnace, arc lamp, pencil core, and so on.

GRAPHITE BLOCKS FOR SALE

EDM Graphite Block

As China's manufacturing industry is moving towards high-end development, the country is vigorously promoting intelligent manufacturing. Therefore, in the field of precision mold manufacturing, the requirements for the discharge materials used in the processing are becoming higher and higher, so THE position of EDM graphite in the processing of these precision molds is becoming higher and higher, and the screening of EDM materials has been highly concerned by the industry.

Isostatic Graphite Block

Isostatic graphite is made of high purity graphite and has isotropy. Isostatic graphite is a new carbon graphite block developed in the world in the past 50 years, which is closely related to today's high technology. It is irreplaceable for manufacturing single crystal furnaces, graphite crystallizer for metal continuous casting, graphite electrode for EDM, and also an excellent material for decelerating and reflecting materials of rocket nozzles and graphite reactors.

Molded Graphite Block

Molded graphite welding block have a very wide range of properties such as mechanical strength, friction resistance, density, hardness, conductivity and so on, and can be further improved by impregnating resin or metal. Because the molded graphite particle size and internal structure of homogeneity, if not considering the size of the reason he can be used to replace isostatic graphite.

Extruded Graphite Block

Extruded graphite block is a kind of extruded graphite material, mostly used for processing graphite crucible, graphite boat, graphite mold, graphite rotor, graphite heating body, graphite chiller, etc. This kind of graphite carbon block can also be used in strong acid, strong alkali, strong corrosive environment, such as rare earth smelting, chemical industry and so on.

High Purity Graphite Block

High purity graphite block refers to the graphite carbon content >99.99%, the flake crystal integrity, thin and good toughness, excellent physical and chemical properties, with good thermal conductivity, temperature resistance, self-lubrication, conductivity, thermal shock resistance, corrosion resistance, easy to precision machining and other advantages, is the ideal inorganic non-metallic materials.

High Density Graphite Block

OEM carbon high density graphite blocks are widely used in machinery, casting, and metallurgy industries, with high market benefits. Density is one of the parameters that affect the quality of graphite blocks. High-density graphite blocks have a longer service life, and the density of graphite blocks should be guaranteed above 1.7g/cm³.

WHAT ARE GRAPHITE BLOCKS USED FOR?

What Are graphite block uses?

Carbon graphite blocks is used in silicon carbide furnaces and other metallurgical furnaces, resistance furnace lining, and conductive material, graphite vacuum furnace as well as permeable graphite heat exchanger.

What Are Graphite Blocks Used For?

OEM graphite block is widely used in semiconductor, metallurgy, continuous casting, photovoltaic, EDM, chemical, steel, glass and ceramics, and other fields. The quality of China carbon graphite block is good with stable performance.

How to make graphite blocks?

Our OEM carbon graphite block mainly uses high-quality petroleum coke as graphite block material, coal asphalt, or synthetic resin as the binder.

Through the preparation of raw materials, ingredients, mixing kneading, pressing, crushing, remixing kneading, molding, many times of roasting, many times of dipping, purification and graphitization, machining, and made of graphite block.

FAQ OF GRAPHITE BLOCKS

Q:

Who is WH Graphite?

Our headquarter is located in Henan, China. Since 2018, our products have been sold to domestic market (60.00%), North America (10.00%), East Asia (9.00%), Africa (8.00%), South Asia (7.00%), Middle East (3.00%) and Western Europe (3.00%).

Q:

How can WH Graphite guarantee the quality of your solid graphite block?

Q:

What graphite products can you buy from us?

Q:

Why do you buy graphite products from WH Graphite?

Q:

What services can WH Graphite provide?

Want to know graphite block price or buy graphite block, contact us.

- このできごとのURL:

コメント