Rapid Injection Molding

(2024年01月29日)https://www.xinpinmodel.com/rapid-injection-molding/

What is Rapid Prototyping Injection Molding?

Rapid injection molding is the rapid tooling technique by the infusion of plastic into the steel cavity mold which is a common use for making high-quality end parts production. It is the most efficient way to produce plastic parts in high volumes for commercial and functional using.

As one of professional rapid injection molding suppliers, rapid injection molding companies, rapid injection molding factories, we offer machining and finishing services to make tools from a wide range of materials and can produce 50 to 100,000+ finished parts. With our material verification and quality processes, we can ensure your tools and parts are out of your expectations.

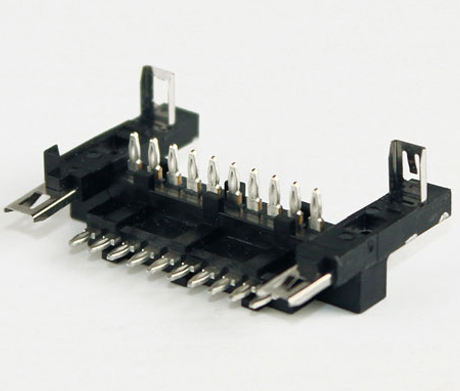

Specification of Rapid Injection Molding

China Rapid Injection Molding Process

China rapid heating and cooling injection molding process typically consists of the following step.

1. Mold Making

The mold will be done by CNC machining and EDM according to the structure of the parts.

2. Material Preparation

The Plastic resin comes from raw pellets.

3. Injection of Melted Resin

The heated mold closes automatically and resin, under great pressure, is injected through a gate and into the mold cavity.

4. Cooling and Solidification

The mold is cooled in a short amount of time to solidify the part inside.

5. Injection of Final Part

The mold opens and the part is ejected to begin a new cycle.

Advantage of Rapid Injection Molding Prototyping

1. Economical And Pratical

We offer a free design-for-manufacturability analysis to make production optimization for improving our customer profit and minimizing losses.

2. A Wide Variety of Plastic Materials

There are thousands of different types of materials to choose from that enable you to achieve your need for your design.

3. Long Term Mold And for Production

Normally 100000+ lifetime that you can repeated use to make parts.

4. Premium Quality And Precision

As the certified rapid prototyping company, all our parts follow a stringent in-house quality control service that ensures that we deliver the best.

FAQs of Rapid Molding

1 How thick can you injection mold?

On average, the minimum wall thickness of an injection molded part ranges from 2mm to 4mm (080 inches to 160 inches).

How do I consider a plastic material for the injection mold?

There are quite a few factors to consider-cost, durability, surface finish, strength, and flexibility are some of the most important ones. You also need to think about how and where your plastic part will be used.

Can take the mold away manufacturing the parts by other?

Of course, you can, you just pay us the mold cost can take it away.

Why should I choose plastic injection mold?

It is a fast and cost-efficient way to create a few prototypes in a selected material for function and aspect testing, as well as for low-volume manufacturing to test out the market.

Xin Pin dedicated to provides high-quality products and services, and also meets the procurement needs of customers of different sizes by CNC Machining, 3D printing, Metal Sheet, Vacuum Casting, Injection Molding, Extrusion, Die Casting and post-processing finishes to make your idea and innovation achieve in different field.

- このできごとのURL:

コメント