Sterolithography Apparatus

(2023年08月08日)https://www.xinpinmodel.com/sterolithography-apparatus/

SLA 3d Printing Service

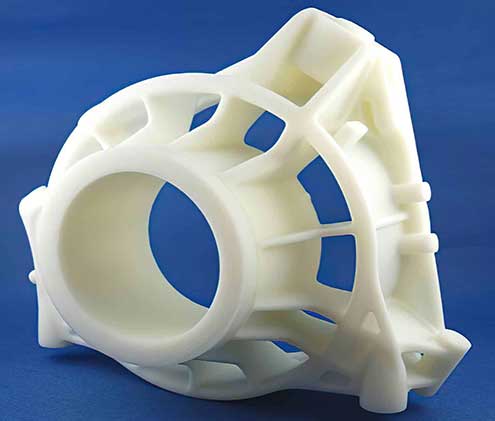

SLA 3D printing (stereolithography) uses an ultraviolet laser that draws on the surface of liquid thermoset resin to create thousands of thin layers until final parts are formed. A wide selection of materials, extremely high feature resolutions, and quality surface finishes are possible with SLA 3D printing.

Specification of SLA 3D Printing

Item NameStereolithography (SLA)

Working Platform Size1100X700X500mm

Maximum Build SizeUp to 145 × 145× 145 mm

MaterialMost common – nylon and its various mixed, sometime PEEK is also used

Lead Time3-5days

Dimensional Accuracy± 0.5% with a lower limit of ± 0.15 mm

Layer Thickness50-100 μm

Applicationpatterns, molds, clear part, functional prototyping, medical device, dental applications, etc

How does Selective Laser Sintering Work?

The SL machine begins the 3D printing process by drawing the layers of the support structures, followed by the part itself, with an ultraviolet laser aimed onto the surface of a liquid thermoset resin. After a layer is imaged on the resin surface, the build platform shifts down and a recoating bar moves across the platform to apply the next layer of resin. The process is repeated layer by layer until the build is complete.

Newly built parts are taken out of the machine and into a lab where solvents are used to remove any additional resins. When the parts are completely clean, the support structures are manually removed. From there, parts undergo a UV-curing cycle to fully solidify the outer surface of the part.

We can offer kinds of stereolithography apparatus for sale, if you have needs, please contact us.

If you want to know more details of stereolithographie definition, stereolithographie material, stereolithographie video and stereolithography apparatus working principle, please visit our website.

Xin Pin Model is a professional rapid prototyping 3d printing factory in China. We have developed a one-stop china machining services solution from rapid prototyping to mass production. As an experienced cnc machining factory, Xin Pin manufacturing capabilities include injection molding service, compression molding service, CNC machining service, metal stamping service, 3D printing service, etc.

- このできごとのURL:

コメント