Sheet Metal Fabrication

(2023年08月07日)https://www.xinpinmodel.com/sheet-metal-fabrication/

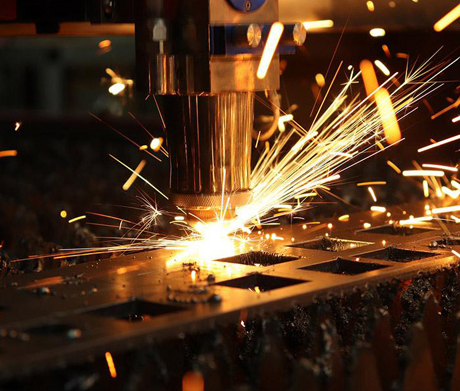

What is Sheet Metal Fabrication Services?

Custom sheet metal fabrication use variety methods throgh cutting, welding bending, punching and stamping processes to force the flat and thin metal into the desired shape. It is an ideal solution for metal components with specified wall thickness.

Whatever your requirement and demands, as one of sheet metal fabrication manufacturers, Xin Pin have capability enough to supply quick prototyping and volume production with very fast leadtime. Contact us today for a free sheet metal manufacturing quote.

Specification of Sheet Metal Fabrication

CapabilityLaser Cutting, Bending, Punching, Welding, Waterjet Cutting

Raw Material FormsSheet

Maximum Dimensions990.6mm x 1,193.8mm

Minimum Dimensions6.35mm x 6.35mm

ToleranceNormally ±0.05mm, and it depends on part features such as bends, offsets, holes, and inserted hardware.

Production VolumeFrom 1pcs to Prototype Medium Volume (5,000+ Parts)

Surface FinishingBrushing, Plating, Powder Coating, Abrasive Sand Blasting

Lead Times AvailableShortest 5-7 Days

Quoted on The Job by Job Basis

Emergency Services Available (AOG)

IndustryAerospace

Commercial

Electronic

Marine

Military

How to Sheet Metal Fabrication

Metal Sheet Fabrication has a wide application. The fabrication method usually depends on the size of the part, the complexity of the design, and the finish type. but it is no more than the following process. As follows,

1. View Drawing

It is the first and the most important process to production.

2. Blanking The Material

Actually, there are many ways of blanking. We always choose the one suitable for your parts.

A. Blanking by the shearing machine. It used to cut out the width and length material.

B. Punching Blanking

C. NC Blanking

D. Laser Cutter Blanking

3. Flanging, riveting bending, welding as a requirement.

4. Surface Treatment

Generally has electroplating, Painting, Anodizing, etc.

5. Assembly

Assembly is the final step for the whole part. It should be taken care of on the surface without a scratch.

The Advantage of Sheet Metal Fabrication Services

1. Economical Cost

Sheet metal parts can make large volumes of end parts at a lower cost per unit. It is one of the economical prototyping techniques.

2. Fast Leadtime

We utilize our year's experience with the advanced tools and technologies to machine high-quality parts on short timelines (Normally 7 to 14 days).

3. Complex Geometry

We can fabricate the complex structure through cutting, welding bending, punching, and stamping processes.

4. Remarkable Quality

Most sheet metal parts can be used directly to the end-use product after painting or plating.

5. Low Volume Production

From 1pcs to 100000+ pcs, it is a very effective way to fabricate your parts with our capability.

Xin Pin Model is one of professional rapid prototyping suppliers in China. We have developed a one-stop china machining services solution from rapid prototyping to mass production. As an experienced cnc machining exporter, Xin Pin manufacturing capabilities include injection molding service, compression molding service, CNC machining service, metal stamping service, 3D printing service, etc.

- このできごとのURL:

コメント