Warehouse Automation Expert

(2024年06月05日)https://www.hairobotics.com/warehouse-robots

Intelligent Case-to-person Solution

As a warehouse expert, Hai Robotics provides highly efficient Goods-to-Person solutions for warehouse logistics transportation and process optimization.

Our solution uses Automated Case-handling Mobile Robot (ACRs) to store and retrieve several cases at a time in tall, narrow storage aisles. This dense storage configuration can enable operations to reduce square footage dedicated to storage, while actually increasing total storage capacity. Once cases are retrieved, the robots work in a goods-to-person framework, moving inventory into position to fuel order fulfillment and other logistics processes.

Combining advanced robots in warehouse logistics and AI algorithms, Hai Robotics ensures superior performance in environments that require maximum uptime, accuracy, and efficiency.

Why Choose Us

warehouse robots for distribution centers

3-4 TIMES

Increase your operational efficiency

by 3-4 times

400%

0.2m-10m storage range

Increase storage density by 80-400%

Achieve picking accuracy of 99.99%.

99.99%

Achieve picking accuracy of 99.99%.

Industry Challenge

More and more industries face immense challenges as they struggle to meet customers' changing demands on time.

With fluctuations in demand, business owners need a flexible and scalable automated solution to meet the growing demand while integrating easily with existing infrastructure and systems.

See How our solution improves operational efficiency and storage density at a low cost.

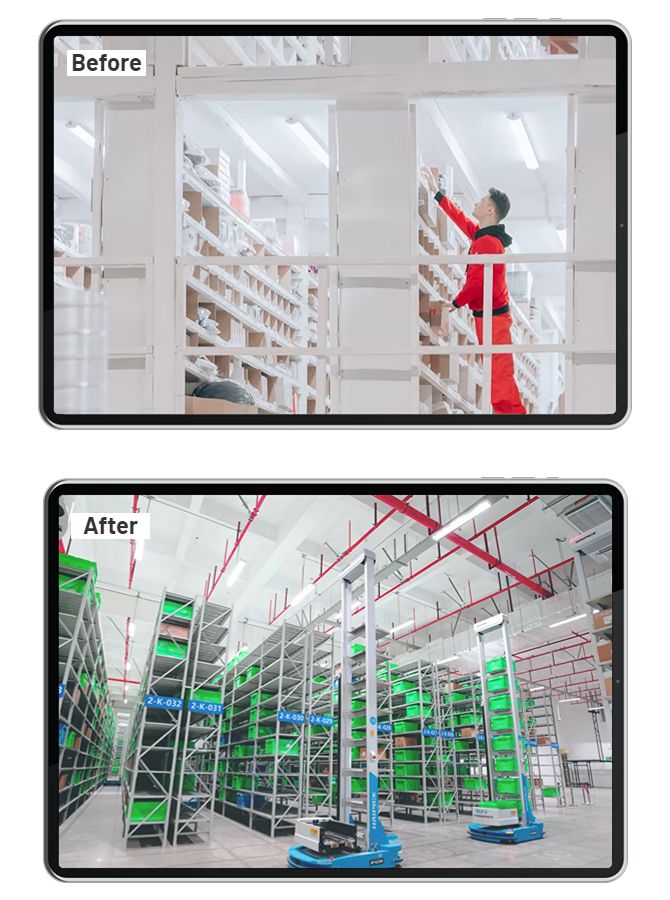

Challenge: Inefficient Manual Processes

As delivery channels and consumer demand is growing, the necessity for more efficient fulfillment practices becomes critical for success.

Our automation solutions will bring you the following values:

300%-400% Higher Operation Efficiency

99.99% Picking Accuracy

Challenge: Low Storage Density

Managing inventory in your warehouse or DC is one of many challenges business owners face along the supply chain, and a primary challenge in a DC is limited space.

Our automation solutions will bring you the following values:

80%-400% More Storage Density

50% Reduced Aisle Width in the Racking Area

Make Full Use Of Vertical Space

Our Products

The ACR (Automated Case-handling Mobile Robot) was independently developed by Hai Robotics. It can realize intelligent picking, storage and simultaneous handling of multiple cases.

As a new intelligent logistics handling device, it can realize intelligent moving in the warehouse without the help of any track. It has the functions of autonomous navigation, active obstacle avoidance, and autonomous charging.

HaiPick A42

Multi-Layer ACR

The HaiPick A42 autonomous warehouse robot is the ACR (Automated Case-handling Mobile Robot) independently developed by Hai Robotics. It can realize intelligent picking, storage and simultaneous handling of multiple cases (up to 300kg on a single trip).

Telescopic Lift ACR

The HaiPick A42T warehouse robot adopts a telescopic lift function independently developed by Hai Robotics, providing warehouse automation solutions with ultra-high storage density reaching up to 10m high.

HaiPick A42

Multi-Layer ACR

The HaiPick A42 warehouse robot is the ACR (Automated Case-handling Mobile Robot) independently developed by Hai Robotics. It can realize intelligent picking, storage and simultaneous handling of multiple cases (up to 300kg on a single trip).

Fork-Lifting ACR

The new HaiPick A3 warehouse robot adopts fork-lifting picking technology and an 8-layer ultra-high storage design. It supports multi-form and multi-size goods picking and handling and provides mixed solutions for material turnover scenarios.

Industry Solution

Our solution has increased warehouse operation efficiency by 3-4 times and storage density by 80%-400% for clients including DHL Supply Chain, BEST Supply Chain, Phillips, and many others. The solution has been applied in 3PL, apparel, e-commerce, electronics, energy, manufacturing, pharmaceuticals, and several other industries.

If you want to know more about robotics in supply chain, please visit our website.

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント