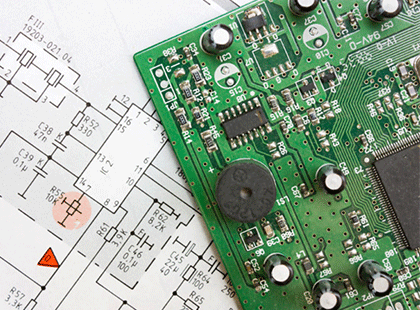

PCBA/PCB ASSEMBLY

(2021年12月06日)https://www.zfpcba.com/pcb-assembly/

ZF Electronics, as one of the top printed custom circuit board manufacturers and PCB manufacturing companies in China, can provide customers with single-sided PCB, double-sided FR4 PCB, metal core PCB, heavy copper PCB, rigid PCB and rigid-flex PCB.

Available PCBA Services

ZF provides fast, low-cost but excellent electronic PCBA board assembly fabrication and professional services, PCB assembly electronics manufacturing and a full set of all PCB printed circuit board assembly services. From electronic component procurement, the printed circuit board prototype, PCB production operations, PCB production and assembly, soldering, PCBA function testing to finished products, we provide you with one-stop packaging logistics of PCB printing service, which is your best choice for PCBA outsourcing!

Six Types of PCBA Assembly

Surface-mount Technology(SMT) A+ssembly

Ball Grid Array (BGA) Assembly

Hybrid Technology (SMT and Through Hole)

PTH Plated Through Hole Assembly

Mixed PCBA technology Assembly

Kit Assembly

PCBA Function Test

ICT test: Mainly include circuit on-off, voltage and current values and fluctuation curves, amplitude, noise, and etc.;

FCT test: Simulate the function of the entire PCBA board and find the problems in the hardware and software;

Fatigue test: Observe whether there is failure and judge the probability of failure in the test;

Test in harsh environments: Expose the PCBA board to extreme temperature, humidity, drop, splashing, and vibration to obtain random sample test results, thereby inferring the reliability of the entire PCBA board batch product;

Aging test: Power on the PCBA board and electronic products for a long time, keep the printed circuit design & fab circuits assembly PCBA working and observe whether there are any failures. The components are installed manually by experienced engineers during PCB manufacturing assembly.

- «前のできごと |

- 次のできごと»

- このできごとのURL:

コメント